Tangible Industries envisions a future where technology and nature work in harmony to inspire innovation, deepen understanding, and drive sustainable progress. We aim to redefine what’s possible by replicating the sophistication of natural systems, transforming data into actionable insights, and creating solutions that empower industries to build smarter, more adaptive, and interconnected designs. Through our advancements in Tangible Intelligence, we strive to pioneer a world where human ingenuity and natural intelligence converge to shape a more sustainable, informed, and innovative future.

OUR VISION

At Tangible Industries, our mission is to harness the intelligence of nature through advanced technologies, enabling groundbreaking discoveries and transformative solutions across industries. By merging data-driven design, generative modeling, and additive manufacturing, we strive to reveal and replicate the intricate patterns, structures, and relationships that define the natural world. Our goal is to inspire innovation, advance scientific understanding, and create tools that empower industries to design with precision, sustainability, and purpose—bridging the gap between nature and technology to shape a smarter, more connected future.

OUR MISSION

Our technology was born out of Harvard University and the Inworks Innovation Initiative, an acclaimed design and engineering studio, that is situated at the University of Colorado Anschutz Medical Campus.

OUR STORY

This work is a truly collaborative team effort involving designers, architects, mechanical engineers, computer scientists, clinicians, radiologists, and surgeons across a variety of disciplines to propel the work and research forward. This team collaborates to offer meaningful and advanced solutions to some of today’s most challenging issues in the medical, design, engineering, fashion, and architecture worlds. Meet our team of visionary designers, skilled engineers, and innovative creators dedicated to transforming ideas into tangible realities:

Our Team

NICHOLAS JACOBSON, Founder

An architect, scientist, engineer and inventor, Nicholas Jacobson has led the creation of scientific research and technologies with an emphasis on integrative design across scales and disciplines.

Interested in the intersection of technology, culture and design, nicholas jacobson is a resident of Aspen Colorado and 2015 graduate in the Master of Design Technology Advanced Studies Program from Harvard University Graduate School of Design.

Trained as an architect and artist, with a particular interest in a technique-concept search for innovation through digital fabrication and emerging technologies. Seeking to first understand the pressing issues and concerns and then looking to design technologies that explore construction methods, local and innovative materials and site/program in the deepest ways possible before an intervention/invention is made. The goal is always to avoid mere stylistic exercises and search for a design aesthetic though integrating the site, structure, form, performance and program that address the issues in such a way as to create a novel and holistic design. Every project is a new project and every outcome is a uniquely adapted and answers the question of what we want to live on a level deeper than aesthetics alone.

Nicholas's work and research has lead to a diverse range of collaborations resulting in unique and innovative projects. Such collaborations include: Harvard's Wyss Institute for Biologically Inspired Design, Anderson Ranch Arts Center, MIT Media Lab Mediated Matter Group, MIT AeroAstro Department, Harvard Business School. His work and research has been published in both nationally and internationally though the design and science communities.

His hobbies as an artist have been borne out of the by-products found in the process of innovation and experimental fabrication. So often overlooked as failures these by products can prove informative by illuminating the process of creating. Pushed further these off-shoots can prove useful in unintended ways. This work can be seen around Columbia, Colorado, the Midwest, New York City, Spain, and most recently Harvard Yard.

JORDAN LEWIS, Co-Founder and CEO

Jordan Lewis is a veterinarian and entrepreneur who has focused on startups within the life sciences. Skilled at integrating medical knowledge with business innovation, he has successfully navigated complex multi-disciplinary regulatory frame-works while pioneering new business ventures. His experience spans the full life cycle of startups: from inception, fundraising, execution to operations. He received his Veterinary Medical Degree (VMD) in Medicine and Surgery from the University of Pennsylvania in 2008.

Nick and Jordan have been working together since 2016. They met after Jordan read an article about Nick’s recent project featured in Vogue. Jordan hired Nick and his team to consult on numerous projects for his cannabis companies.

Rob Ducey, Co-Founder

A failed professional soccer player, I have over 25 years of experience working in visual effects and animation. My career started in scientific visualization and entertainment production at a small company in Ames, Iowa. This led to an opportunity as a technical director and visual effects artist at Big Idea Productions in Chicago, known for their popular series, VeggieTales. Nearly twenty years ago I left that studio for Vinton in the rainy Pacific Northwest, a commercial production studio at the time most identified with the California Raisins and the iconic M&M's characters. I first became acquainted with 3D printing when the Knight family rebranded the studio LAIKA and began production on Coraline, our first feature film. On that production, we pioneered the use of 3D printers to produce the facial animation for the main characters, generating thousands of parts for a technique known as replacement animation. On every subsequent film I have been involved in the further development and expansion of that process which was received a Scientific and Engineering Award from the Academy of Motion Pictures Arts and Sciences in 2016. Today I am the technical supervisor for the Rapid Prototyping department responsible for integrating additive manufacturing technology with many of our production processes as we work on our sixth feature, Wildwood. Additionally, I support Nick and his team at InWorks to apply my knowledge of digital design and additive manufacturing on their many projects. I am a member of AMPAS, VES, and ASIFA.

Christodoulos Kaoutzanis, Advisory Board

I perform both aesthetic and reconstructive surgery. My clinical areas of interest include breast reconstruction, aesthetic surgery, transgender surgery, and reconstructive microsurgery including the surgical management of lymphedema. Using the most advanced techniques I reconstruct oncologic, traumatic, and congenital defects throughout the body. I also perform cosmetic surgery of the face, eyes, neck, breasts, abdomen, body, and genitalia. In addition, I work very closely with a multidisciplinary team to provide the whole spectrum of gender-affirming surgeries (both feminizing and masculinizing).

Selected Publications

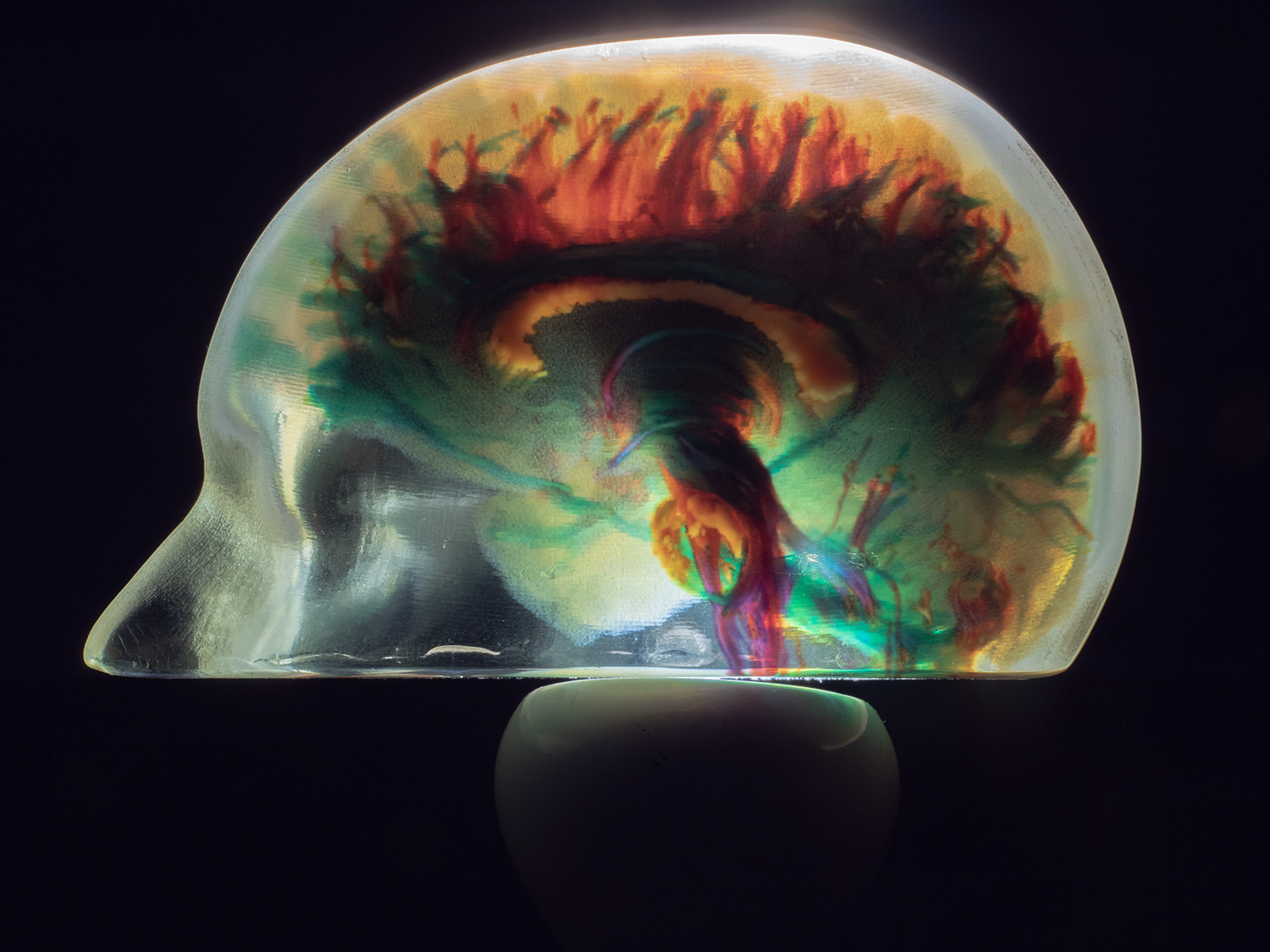

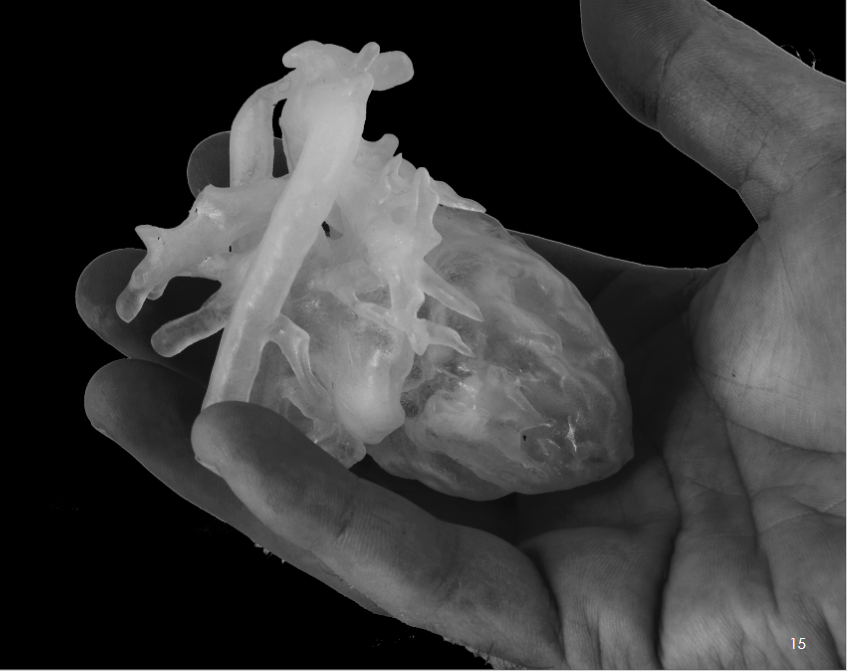

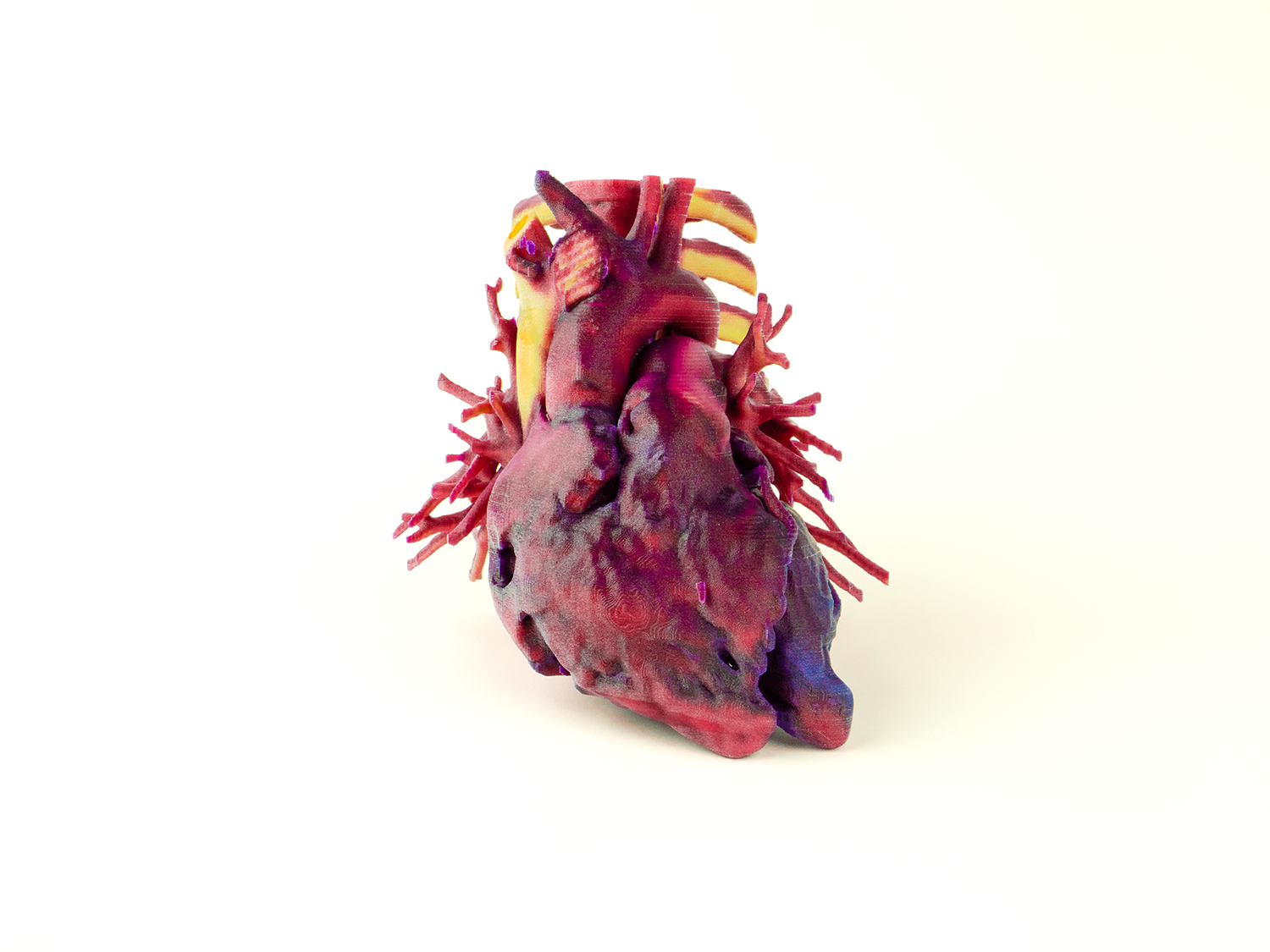

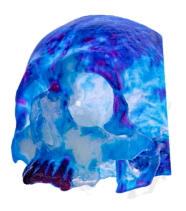

The Inner Complexities of Multi-modal Medical Data: Bitmap-based 3D Printing for Surgical Planning Using Dynamic Physiology. 3D Printing and Additive Manufacturing. Authors: Jacobson, N.M., Brusilovsky,J., Ducey, R., N. V. Stence, A. J. Barker, M. B. Mitchell, L. Smith, J. C. Weaver. (2023)

Voxel Printing Anatomy: Design and Fabrication of Realistic, Presurgical Planning Models through Bitmap Printing. J. Vis. Exp., e63214, In-press (2021). Authors: Jacobson, N. M., Smith, L., Brusilovsky, J., Carrera, E., McClain, H., MacCurdy, R.

Defining Soft Tissue: Bitmap Printing of Soft Tissue for Surgical Planning. 3D Printing and Additive Manufacturing. Authors: Jacobson, N. M., Smith, L., Sheridan, A, Stence, N., J., Carrera, E., Browne, L., MacCurdy, R. 28 Apr 2022

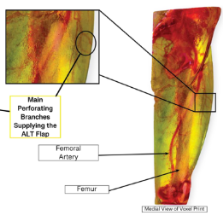

Hybrid modeling techniques for 3D printed deep inferior epigastric perforator flap models 3D Printing in Medicine, In-press (2023). Authors: Jacobson, N. M., Carrera, E., Treat, A., McDonnell, M,. Mathes, D., Kaoutzanis, C.

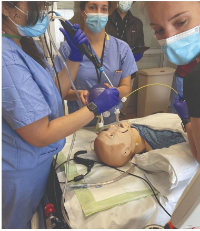

Digital workflow for high-risk, low-volume procedure simulation. Journal of Biomed Research. Authors: Jacobson, N. McClain, H., New, M. Mar 2022

Contingency planning for healthcare worker masks in case of medical supply chain failure: Lessons learned in novel mask manufacturing from COVID-19 Pandemic. Authors: Cumbler E, Wittig M, Jacobson N, McClain H, Treat A, Radin J, Stowell S, Harry E. American Journal of Infection Contol, 08/03/2021

Rapid Prototyping Airway and Vascular Models from 3D Rotational Angiography: Beans to Cup 3D Printing. Authors: JE Zablah, SA Rodriguez, N Jacobson, GJ Morgan Progress in Pediatric Cardiology, 101350. 2021

Computational Design in Creative Industries in: “CODIFY Computation in Landscape Architecture”. Authors: Friedman, J. Jacobson, N. Cantrell, B. Mekies, A. Routledge 2018

Voxel Beam: Topology Optimization for Mulit-Material 3D Printing. Authors: Hosny,A., N Jacobson, Seibold, Z. CAADRIA. 2015 & GSD Platform. 2014

3D printing for an anterolateral thigh phalloplasty 3D Printing in Medicine, In-press (2023). Authors: Walker, M., Kaoutzanis,C., Jacobson, N. M.

Awards

Liver Long and Prosper Journal of Anatomy, In-Review (2024). Authors: Kim, A., Jacobson, N. M.

Face Fixin' Journal of Anatomy, In-Review (2024). Authors: Tripp, K., Jacobson, N. M.

2024 Anschutz Accelerator Initiative

Co-Investigator $6,000,000

2023 Children’s Hospital Innovation Grant - Digital Nasoalveolar Molding

Principle Investigator $25,000

2022 State of Colorado Advanced Industries Grant - Digital Nasoalveolar Molding

Principle Investigator $150,000

2022 Align Technology Research Award - Digital Nasoalveolar Molding

Principle Investigator $25,000

2021 Smile Train Grant - Digital Nasoalveolar Molding

Co-Principle Investigator $10,000

2020 AB Nexus Award - 3D Printing for Presurgical Planning.

Co-Principle Investigator: $50,000

2022 Gates Grubstake Award - 3D Printed Implantable Devices.

Principle Investigator $350,000

2021 VA Hospital - Patient-Specific 3D Printed Bronchoscopy Trainer

Principle Investigator $25,000

2021 OEDIT Award State of Colorado Advanced Industries Grant.

Principle Investigator $130,000

2020 AB Nexus Award - 3D Printing for Presurgical Planning

Co-Principle Investigator : $50,000

2017 International Federation of Landscape Architects IFLA AAPME

National Award of Excellence

Our symbol is derived from the phrase “As Above, So Below,” which represents the interconnectedness of the macro and micro, the original and its reflection. In our work of data driven design, this concept embodies our ability to capture the nature of the design—preserving the integrity, detail, and spirit of each specimen—so that what is created mirrors the authenticity of what is or once was.